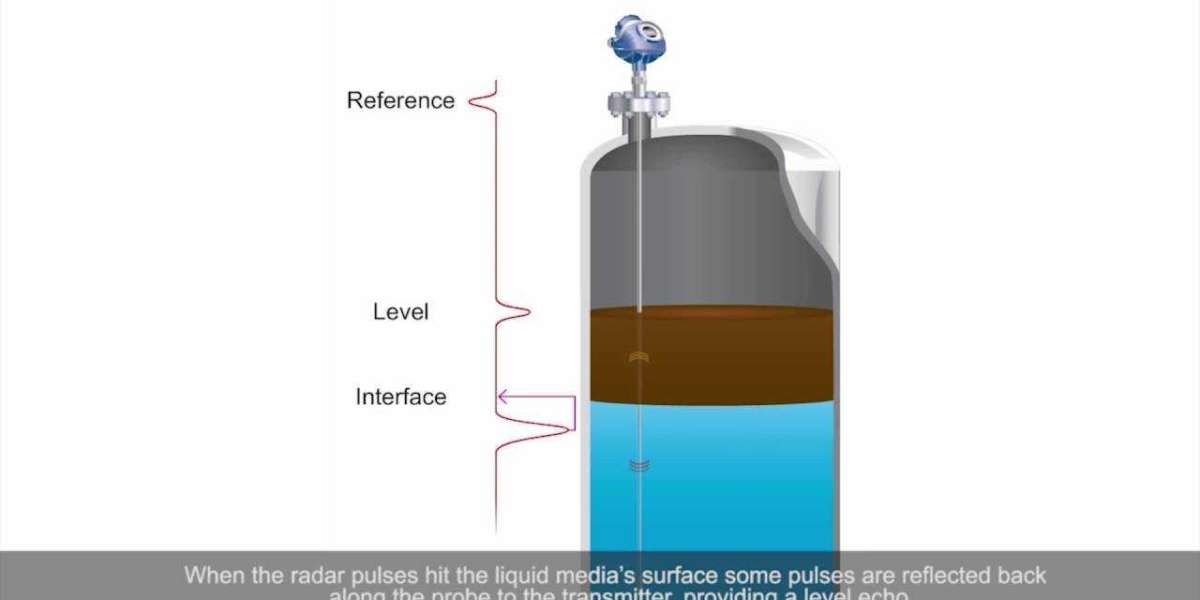

Guided radar level sensors are essential devices that are used in a wide variety of industrial applications because they provide an accurate measurement of the level of liquids, solids, and slurries. Other names for these sensors include time domain reflectometry (TDR) sensors and guided wave radar (GWR) sensors. These sensors make use of microwave signals, which are first sent through a probe and then reflected off the surface of the medium that is being measured. These signals are then utilized in the sensing process. This article will delve into the fundamentals of guided radar level sensors, including how they operate, the principles upon which they are based, as well as the various industries that make use of these sensors. In addition, this article will discuss the various industries that make use of these sensors. Guided radar level sensors work by applying the fundamentals of time domain reflectometry, which is also referred to by its acronym, TDR. While the probe is immersed in the substance that is being measured, an electromagnetic pulse of low energy but the high frequency is transmitted down the probe. The pulse travels all the way from the very top of the probe all the way down to the very bottom of the medium.

When the pulse reaches the surface of the medium, a portion of its energy is reflected back to the sensor. This continues until the pulse has completed its journey through the medium.

In circumstances in which solids or bulk materials are present, as well as in circumstances in which the medium in question has a low dielectric constant or a high dust content, the use of a cable probe or a probe consisting of two rods is the most effective method of investigation. Guided radar level sensors are utilized in a wide variety of different commercial markets on account of their accuracy, dependability, and adaptability. The following are some examples of applications that are frequently used:In sewage treatment plants, reservoirs, and water treatment plants alike, GWR sensors are utilized for level measurement purposes. These facilities are in charge of managing both fresh water and wastewater in their respective areas. In the field of chemicals and petrochemicals, these sensors are utilized for level measurement in storage tanks, reactors, and separators that contain a wide variety of chemicals and petrochemicals. These tanks, reactors, and separators contain a variety of different chemicals and petrochemicals. GWR sensors are able to provide precise and hygienic level measurements in tanks, vats, and silos that are used to store food and beverage products. In the food and beverage industry, these sensors play an important role. The sensors are utilized for level measurement in mixing vessels, bioreactors, and storage tanks within the pharmaceutical industry. This takes place in the course of the production process for pharmaceuticals.

The levels of the contents in hoppers, silos, and thickeners that are used in mining and mineral processing can be measured by guided radar level sensors. Ores, minerals, and other kinds of solid materials could fall into this category.

The ability of guided radar level sensors, also known as time domain reflectometry (TDR) sensors, to provide accurate and reliable level measurements in a diverse array of applications has contributed to the rise in popularity of these sensors over the course of the past few years. This rise in popularity has been attributed to the fact that guided radar level sensors can provide accurate and reliable level measurements. These sensors are able to function by sending electromagnetic pulses along a probe, and then measuring the amount of time it takes for the pulse to reflect back from the surface of the medium that is being measured. In this article, we will investigate the fundamentals of guided radar level sensors, discuss their advantages and disadvantages, and delve into the many applications that make the most effective use of these sensors.

In order for guided radar level sensors to function in accordance with the principles of time domain reflectometry, also known as TDR, it is necessary to transmit an electromagnetic pulse along a conductive probe that is immersed in the medium that is being measured. The pulse travels down the probe, reflects off the surface of the medium, and then returns to the sensor where the guided wave sensor was first detected after it has completed its journey down the probe. The amount of time it takes for the pulse to travel from the sensor to the surface of the medium and then back again is directly proportional to the distance that separates the two points in this equation. Due to the fact that it measures this time, the sensor is able to produce an accurate reading of the level of the medium that is contained within the container.

When it comes to guided radar level sensors, rigid probes are by far the most common type, despite the fact that flexible probes are also an option. Applications that involve heavy buildup or temperatures that are particularly high are good candidates for rigid probes made of stainless steel. Other applications that could benefit from rigid probes include:For use in vessels that are particularly tall or those that have internal obstructions, flexible probes that are made of cable are the preferred option.

Guided radar level sensors provide an adaptable and accurate method of level measurement that is applicable across a variety of business sectors

- These sensors can be used to measure levels in liquids, gases, and solids

- Due to their ability to provide accurate measurements despite challenging environmental conditions and their compatibility with a wide variety of media types, they are an attractive choice for a wide variety of applications

- This is because of their capacity to deliver accurate measurements

- Users who have a fundamental understanding of guided radar level sensors, in addition to their advantages and disadvantages, are in a better position to choose the sensor that is most suitable for their particular needs when compared to other available options