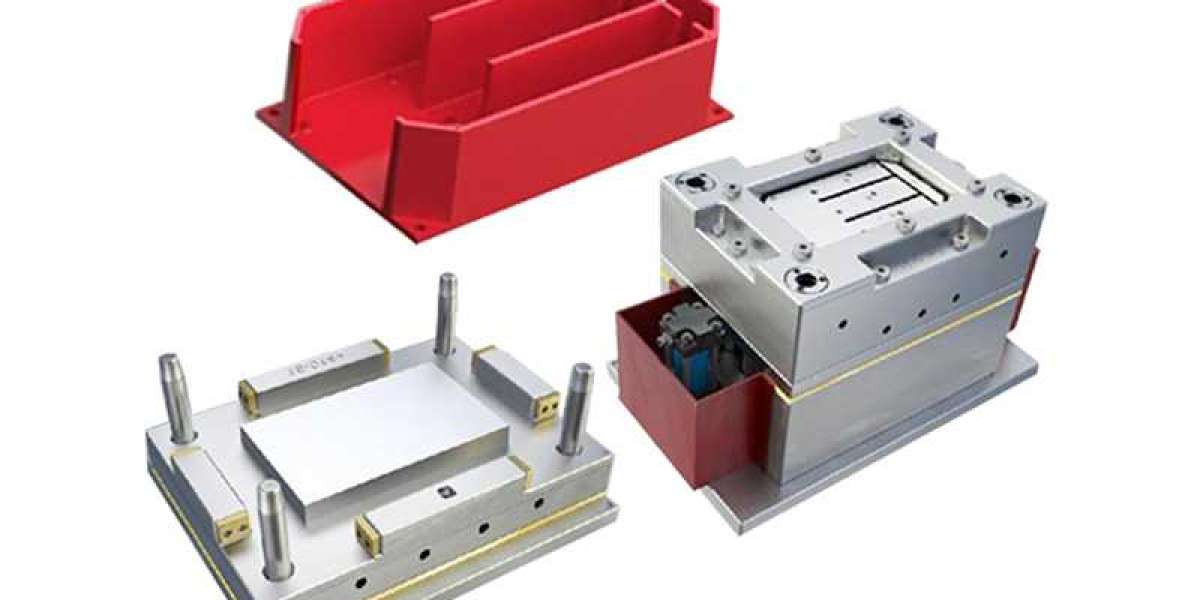

In modern power systems and construction industries, SMC (Sheet Molding Compound) materials are popular for their good performance and cost-effectiveness. As a manufacturer, we focus on the production of SMC meter box mold and SMC circuit breaker box mold. These two products occupy an important position in our production line. This article will conduct an in-depth comparative analysis of these two molds from the manufacturer's perspective.

Let’s start with materials and manufacturing processes. SMC material is known for its lightweight, high strength, corrosion resistance and insulation properties, which makes it ideal for manufacturing meter boxes and circuit breaker boxes. Our SMC meter box mold and SMC circuit breaker box mold both use advanced compression molding technology to ensure product consistency and accuracy. During the manufacturing process, we strictly control the quality of raw materials to ensure that every product meets industry standards.

In terms of design, both SMC meter box mold and SMC circuit breaker box mold are carefully designed to meet the needs of different customers. Meter box molds usually need to accommodate meters, terminal blocks and other related equipment, so their internal structure design must take into account the convenience of space utilization and maintenance. The circuit breaker box mold needs to consider the installation method and ease of operation of the circuit breaker. Our team of designers continuously optimizes mold designs to ensure the final product is both beautiful and functional.