In engineering, ensuring precision and accuracy is paramount, especially when it comes to designing and manufacturing complex parts. One crucial concept that helps achieve this level of precision is "datum."

So, what exactly are datums?

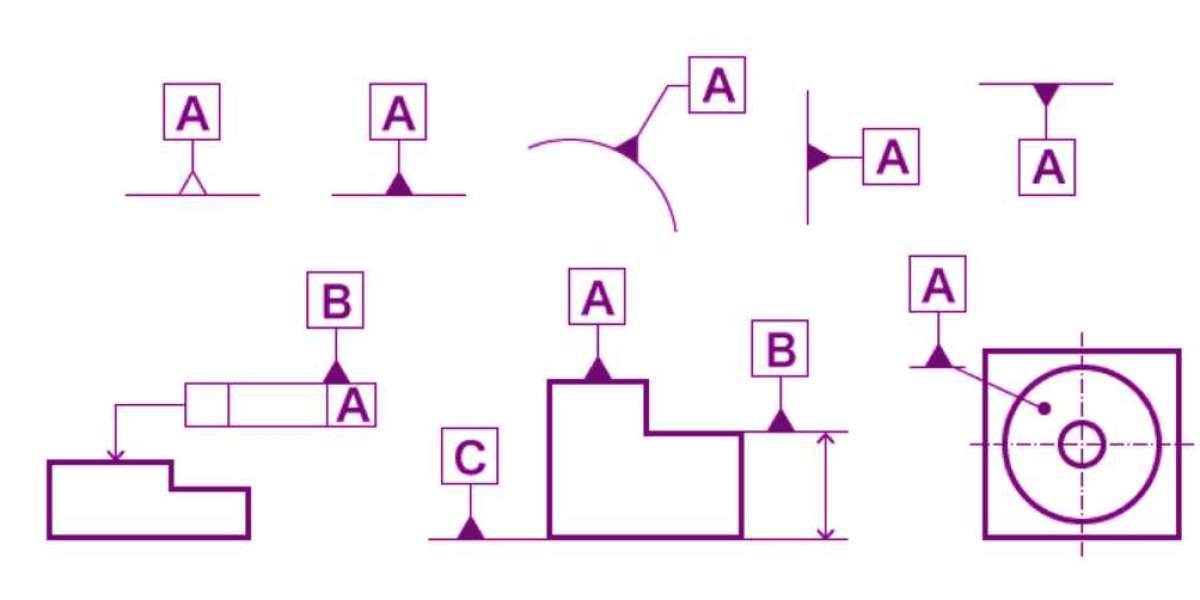

Datums are reference points or surfaces used in the manufacturing and inspection of parts. They serve as the basis for measurements, allowing engineers and machinists to establish consistent alignment and orientation. Think of a datum as the "starting point" for all other measurements on a part. Without a clear datum, it's impossible to achieve the consistency required for high-quality, functional components.

In practical terms, datums are often found in the form of flat surfaces, holes, or specific features of a part. For example, in the aerospace or automotive industries, where precision is critical, datums are used to align components in assembly or for machining processes. They ensure that parts fit together correctly, function as intended, and meet the required tolerances.

When specifying datums, it's essential to understand the various types and how they relate to the design intent. Properly chosen datums simplify the manufacturing process and ensure that parts are easily reproducible and compatible with one another.

In conclusion, datums play a fundamental role in ensuring precision and reliability in the engineering world. Whether for measuring, machining, or assembly, understanding datums helps engineers create high-quality, functional parts.

Reference: