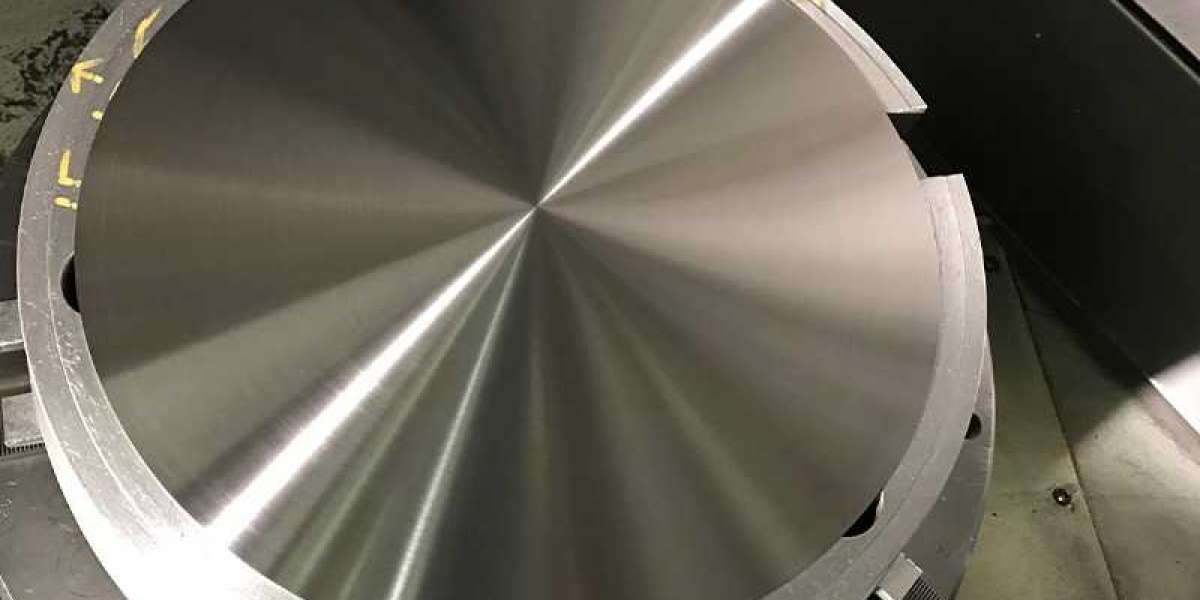

Polishing Finish: Techniques and Benefits

Polishing finish is a crucial aspect of manufacturing and product design, focusing on enhancing the surface quality of materials. This process not only improves aesthetics but also boosts the performance and durability of the finished product.

What is a Polishing Finish?

Polishing finish refers to the process of smoothing a surface to achieve a reflective and smooth appearance. This is typically accomplished through mechanical abrasion, chemical treatments, or a combination of both, depending on the material and desired finish.

Techniques Used in Polishing Finish

Mechanical Polishing

- Involves the use of abrasives and polishing compounds.

- Suitable for metals, plastics, and glass.

- Common tools include polishing wheels and buffing machines.

Chemical Polishing

- Utilizes chemical agents to achieve a smooth finish.

- Effective for complex shapes where mechanical polishing is challenging.

- Often used for materials like aluminum and stainless steel.

Electropolishing

- A specialized form of chemical polishing.

- Removes a thin layer of material to enhance surface smoothness.

- Frequently used in industries requiring high cleanliness, such as pharmaceuticals.

Pros and Cons of Polishing Finish

Pros:

- Enhances appearance, giving products a glossy look.

- Increases corrosion resistance by removing surface impurities.

- Improves functional properties, such as reducing friction.

Cons:

- Can be time-consuming and costly.

- Requires skilled labor for optimal results.

- May not be suitable for all materials or applications.

Applications of Polishing Finish

Polishing finish finds applications across various industries, including:

- Aerospace: Enhances performance and reduces drag.

- Automotive: Improves appearance and protects components.

- Medical Devices: Ensures cleanliness and reduces the risk of contamination.

Tips for Achieving Optimal Finishes

- Select the Right Tools: Match tools to the material for effective polishing.

- Control Speed and Pressure: Adjust these variables to avoid damaging the surface.

- Use Quality Polishing Compounds: High-quality compounds lead to better finishes.

Conclusion

In summary, polishing finish plays a vital role in enhancing the surface quality of products across multiple industries. For those looking to achieve high-quality finishes, professional surface finish services can provide the expertise and resources needed to meet your specifications effectively.

References