Copper is a valuable and widely used metal, making it crucial to maximize copper recovery rates in various industrial processes. One key element in achieving high copper recovery rates is the use of high-efficiency copper dissolving tanks. In this blog, we will explore the impact of these tanks on copper recovery rates, highlighting their novel features and advantages.

1. Enhanced Copper Dissolution

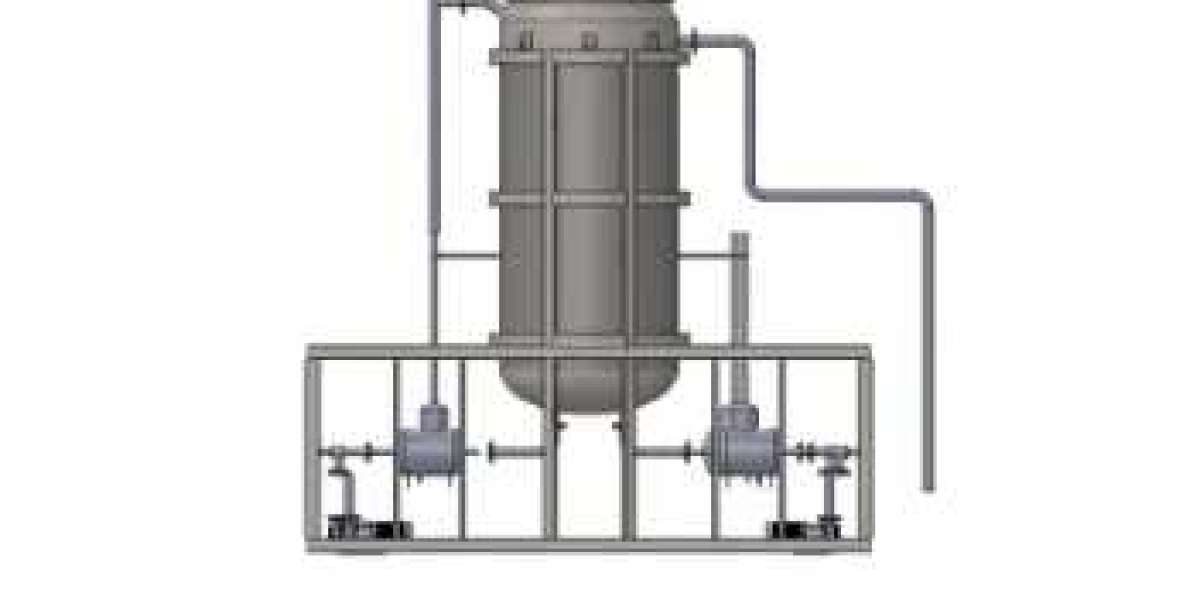

High-efficiency copper dissolving tanks are designed to optimize the dissolution process, ensuring maximum copper recovery. These tanks provide excellent agitation, allowing for efficient mixing of the copper ore or concentrate with the leaching agents. The enhanced agitation increases the surface area contact between the ore and the leachate, facilitating the dissolution of the copper minerals and improving recovery rates.

2. Improved Leaching Agent Distribution

Even distribution of the leaching agent is crucial for optimal copper recovery. High-efficiency dissolving tanks utilize advanced mechanisms to ensure uniform distribution of the leachate throughout the tank. This uniform distribution guarantees consistent contact between the leaching agent and the copper-bearing material, promoting effective dissolution and maximizing recovery rates.

3. Control of Temperature and pH Levels

Maintaining the appropriate temperature and pH levels is essential for efficient copper dissolution. High-efficiency dissolving tanks provide precise control over these parameters. Temperature control systems regulate the tank's temperature, optimizing the chemical reactions involved in copper dissolution. Similarly, pH control mechanisms maintain the desired pH range, ensuring favorable conditions for copper leaching. These controlled environments contribute to higher copper recovery rates.

4. Minimization of Oxygen Consumption

Oxygen is often used as a key leaching agent in copper recovery processes. High-efficiency copper dissolving tanks are designed to minimize oxygen consumption during the dissolution process. These tanks employ techniques such as oxygen sparging or aeration to ensure efficient utilization of oxygen, reducing waste and improving cost-effectiveness. Minimizing oxygen consumption also has environmental benefits by reducing the overall carbon footprint of copper recovery operations.

5. Reduction of Residence Time

Residence time refers to the duration required for complete copper dissolution in the dissolving tanks. High-efficiency dissolving tanks can significantly reduce residence time compared to conventional tanks. The advanced design and optimized operating parameters facilitate faster copper dissolution, accelerating the overall copper recovery process. This reduction in residence time allows for higher throughput and increased production capacity, improving operational efficiency.

6. Enhanced Solids Separation

After copper dissolution, it is essential to separate the dissolved copper from the remaining solids efficiently. High-efficiency dissolving tanks incorporate effective solids separation mechanisms. These tanks often have built-in settling or filtration systems that enable the separation of copper-rich solutions from the solid residue. Efficient solids separation ensures minimal copper losses and maximizes the overall copper recovery rates.

Conclusion

High-efficiency copper dissolving tanks play a vital role in achieving high copper recovery rates. Their ability to enhance copper dissolution, improve leaching agent distribution, control temperature and pH levels, minimize oxygen consumption, reduce residence time, and facilitate efficient solids separation all contribute to maximizing copper recovery. By utilizing these advanced dissolving tanks, industrial processes can optimize copper recovery rates, increase productivity, and minimize waste, ultimately leading to more sustainable and cost-effective operations.

Timonic (Suzhou) Technology Co., Ltd ( Timonic ), a subsidiary of China Special Metal Group Limited (CSM), we commit to the development and production of new energy lithium battery material production equipment: lithium battery copper foil foil machine, cathode roll, especially focusing on providing one-station for high-quality lithium battery copper foil plant design scheme, mechanical and electrical intelligent equipment, software and hardware systems and automation equipment customization and complete sets and technical services.

Welcome to contact us,if you need.

Email:Sales@special-metal.com