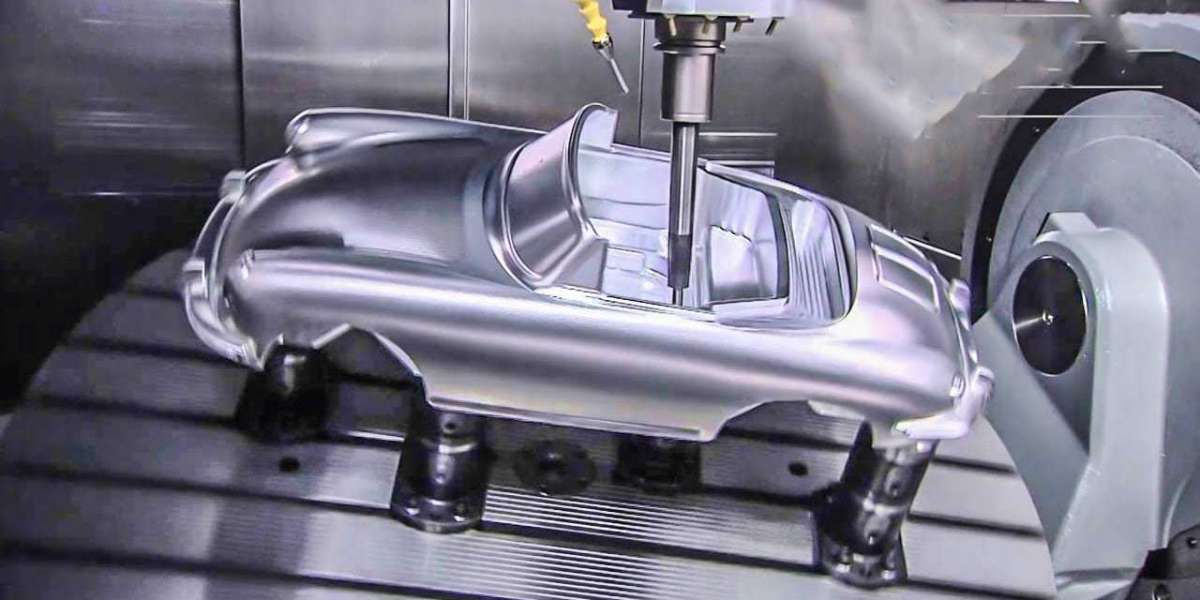

Machining is a step in the production of parts that is very important no matter what material you are working with, be it plastic or metal. It does not matter which material you are working with because this step is very important. because the surfaces of the parts are cut, as opposed to being cast or molded. This is due to the fact that the surface finishes that are produced by machined processes are, in many instances, more than sufficient for the applications that they are intended for. Because of this, the online online machining services might require a higher degree of accuracy, or it might need to make use of some secondary processes.

Either way, it's going to be more work

This is the measurement that is utilized in order to ascertain the level of surface roughness

Take into consideration the fact that the surface of a frying pan made of cast iron has a roughness of approximately 2,000 on the Ra scale

This is just one illustration among many

In spite of the fact that a defect that was less than one-fiftieth the size of a human hair was discovered and did require repair, the ultra-smooth surface of the mirror that is used by the Hubble Space Telescope is as close to zero as it is possible to get

Accidentally finding the flaw led to its identification. These two numbers stand for a range of possible measurements, and the majority of the time, the dimensions of machined parts can be located somewhere in the middle of the range that they represent.

Surfaces that have been machined can on occasion have an acceptable level of roughness in certain scenarios. This is dependent on the specifics of the situation. A surface that is typically favored for aesthetic reasons has a texture that is more uneven than it would be after it has been machined. This is because aesthetic preferences tend to favor surfaces with a more natural appearance. This is due to the fact that uneven textures typically have a greater visual appeal. It is less likely that fingerprints and other smudges will be visible on a surface that has a matte finish, and it also prevents reflections from happening on the surface. Machining, on the other hand, is not capable of producing matte finishes by itself and does not eliminate the necessity of undergoing additional processes.

Movement Across That Is Made Easier to Achieve with Requiring Less Effort to Do So

What kind of feedback or criticism do you think you might receive for the contributions that you've already made? Because every plastic component that was machined is kept in its machined state, the component might still bear traces of the visible tool marks that were used to machine it. This is because every plastic component that was machined is kept in its machined state. On the other hand, particular metal components provide additional opportunities for personalization in their use. In light of this fact, it is essential to keep in mind that precision-machined parts frequently have edges that are razor-sharp.

If you are interested in taking a more in-depth look at all of our design specifications, you can obtain all of the information that you require by consulting these guidelines for CNC milling. These are some general guidelines for CNC milling.

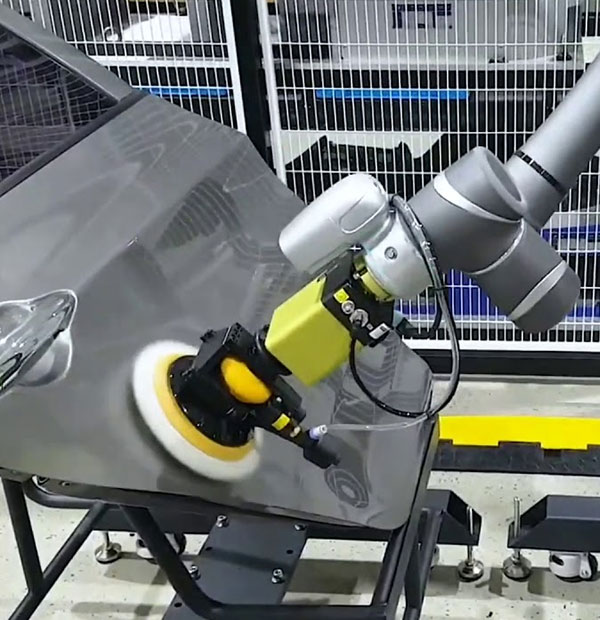

Despite this, the greater roughness of Ra 60 is not something that the vast majority of people would characterize as being rough. Case in point: Case in point: Case in point:One needs to make use of a microscope in order to be able to observe the subtle differences that can be discovered on the surface. This level of roughness can sometimes, depending on the application, lead to incremental wear in a moving part, and it can cause weakness in areas of a part that are stressed. This level of roughness can also cause a part to fail in its intended function. It is not completely out of the question for either of these problems to surface at the same time as the other. These additional processes are the ones that are in charge of the action that is currently taking place at this particular stage of the procedure.

Once the processing has been completed, the procedures that need to be carried out are as follows:

If we want to achieve higher levels of machined parts that have been finished, the secondary finishing procedures are of the utmost significance. For the purpose of achieving this objective, we can choose between a variety of different courses of action. In either case, the component in question will be subjected to a process in which it will be moved back and forth across a series of abrasives that feature grain sizes that become progressively finer as the process progresses. This will be done in order to smooth out any rough spots that may have been left over from the previous step. The number of steps that are applied to the graining procedure determines the ultimate level of surface finish that can be achieved after the graining process.

The ultimate level of surface finish that can be achieved after the graining process can range anywhere from Ra 4 to Ra 32. Lapping is the process that is used to produce precise mirrors for astronomical telescopes, so the fact that this is the case shouldn't come as much of a surprise to anyone because lapping is the process that is used to produce precise mirrors for astronomical telescopes. Lapping is used to produce precise mirrors for astronomical telescopes.

There is some overlap in the relative smoothness that can be achieved by graining or lapping, but the decision to use one process rather than the other can be based on a variety of factors, including price. Graining can be used to achieve a smoother surface than lapping can. Graining can produce a surface that is even smoother than the one that can be produced by lapping, which is a smooth surface.