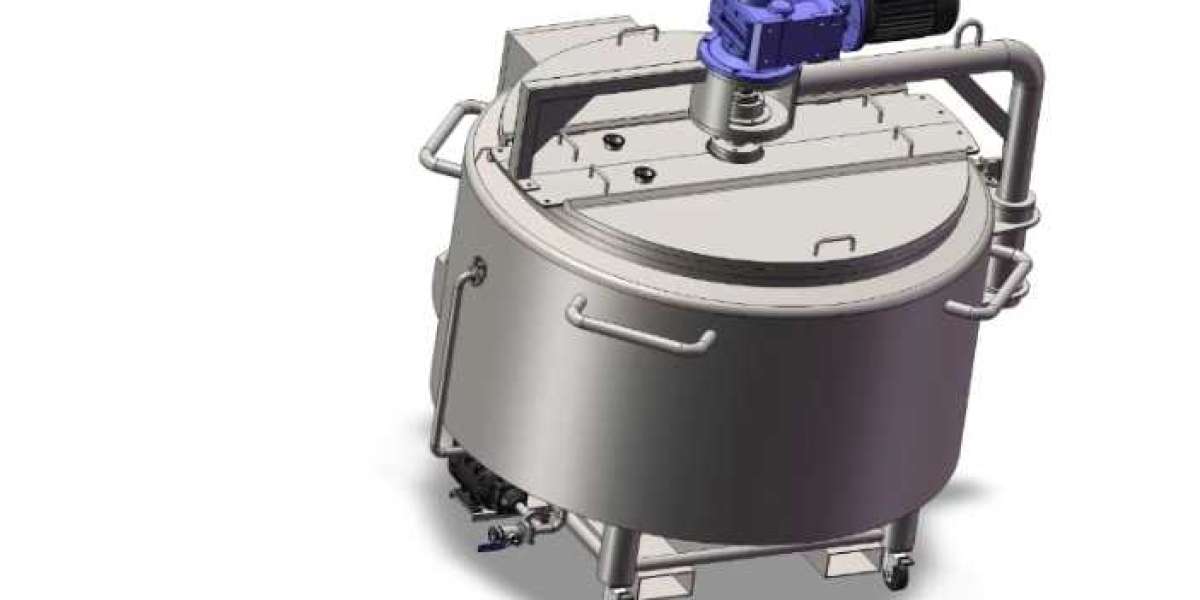

When designing a customized mixing tank, it's essential to consider factors such as the material, configuration, and specific functionality required for your industry. Whether you're mixing paints, pharmaceuticals, food products, or chemicals, a well-designed mixing tank ensures better performance, quality control, and durability.

Material Selection

Stainless steel is the most common material for mixing tanks due to its corrosion resistance and hygiene properties. The typical grades used include:

SS304: Cost-effective and versatile for general applications.

SS316: Ideal for industries with high corrosion risks, such as pharmaceuticals and food production.

SS321: Resistant to high temperatures, perfect for extreme environments.Tank Configuration: Single, Double, or Three-Layer

Depending on your needs, the tank configuration can vary:

Single-Layer: Basic tank body, ideal for simple mixing where temperature control is not needed.

Double-Layer: Includes a heating or cooling jacket for temperature control. Perfect for applications like food or chemical processing.

Three-Layer: Combines a cooling/heating jacket and insulation for advanced temperature management. Best for processes requiring precise temperature control.

Key Features and Functionality

Customized mixing tanks are designed with specific features to meet production needs:

Mixing: Paddle mixers (powered by ABB or Siemens motors) ensure thorough mixing of materials.

Additional Components: Depending on your needs, features like inlets, outlets, spraying balls, manways, and gearboxes can be added for ease of use and efficiency.

Polishing: The tank’s interior is polished with 3A mirror finish, ensuring sanitary standards, while the exterior typically features a 2B satin finish.

Applications Across Industries

Custom mixing tanks are widely used in industries such as:

Pharmaceuticals and Food: Ensuring precise formulations and safe production.

Chemical and Paint Manufacturing: Blending, homogenizing, and controlling temperatures for optimal quality.

Brewing and Research: Tailored to fermentations and experimental setups.

Conclusion

Designing your customized mixing tank allows you to meet the unique requirements of your production process. Whether you're focused on temperature control, material properties, or regulatory compliance, customizing your tank ensures the highest efficiency and product quality. Haishun Machinery, specializing in high-quality brewing equipment and stainless steel tanks, offers tailored solutions to meet the needs of various industries.