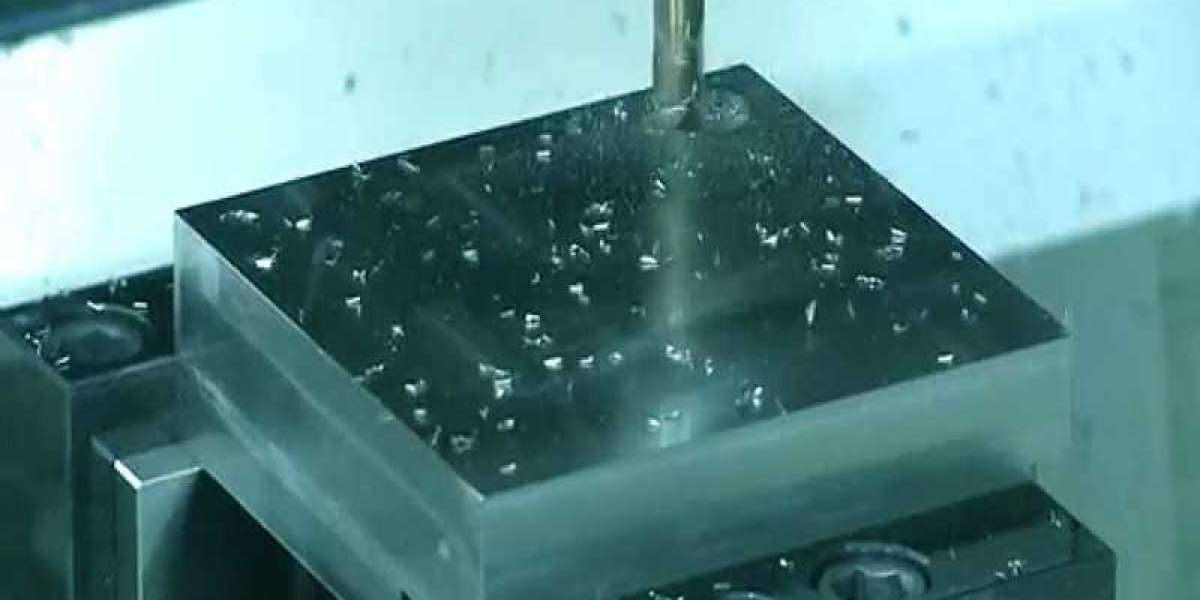

CNC milling stands as a cornerstone of modern manufacturing, with end milling emerging as one of the most widely used methods. This article explores the essential aspects of end milling, including techniques, applications, and the various types of end mills available.

Understanding End Milling

- Overview: End milling utilizes cutting tools with teeth on both the end and sides, enabling the machining of a wide range of shapes and features.

- Uses: This technique is crucial for creating slots, pockets, and intricate contours, making it indispensable across multiple industries.

Techniques Employed in End Milling

- Climb Milling: The cutter moves in the same direction as the feed, resulting in a smoother finish but requiring a stable setup.

- Conventional Milling: The cutter moves against the feed direction, which is easier to control but may produce a rougher finish and increase tool wear.

Different Types of End Mills

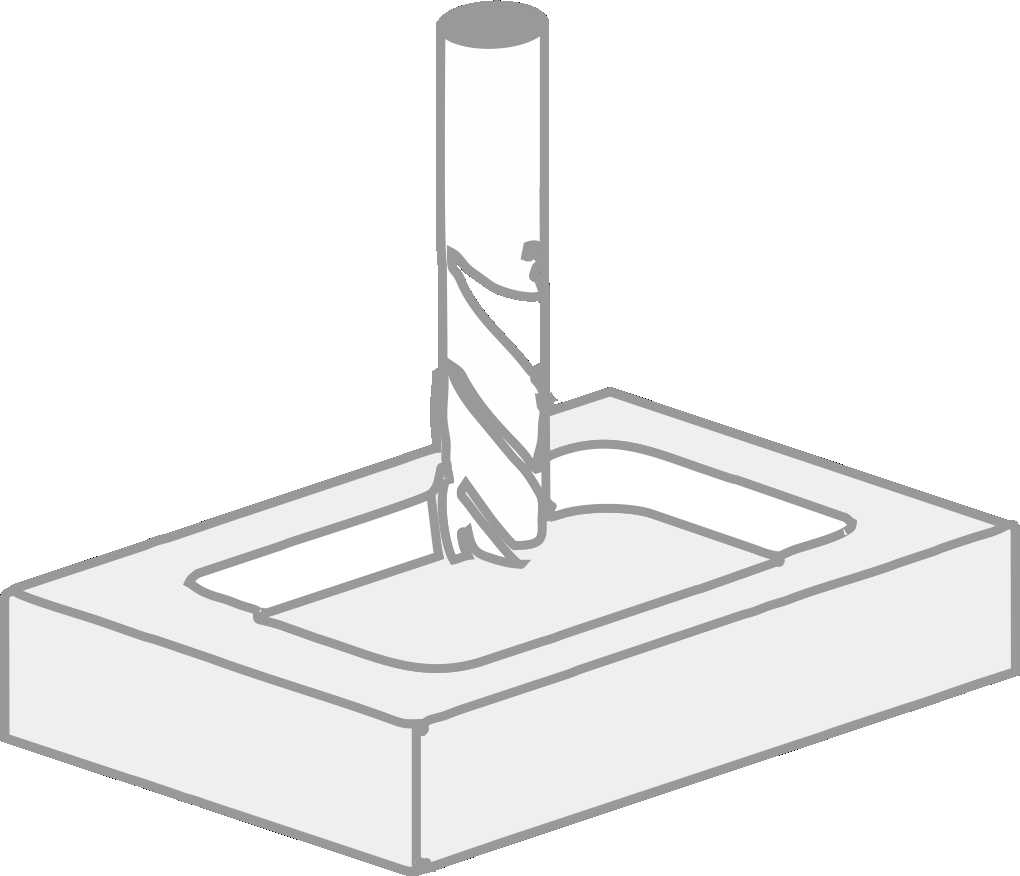

- Flat End Mills: Ideal for machining flat surfaces and pockets, these mills offer robust cutting capabilities.

- Ball End Mills: Designed for creating complex shapes and contours, they excel in finishing operations.

- Corner Radius End Mills: Combining features of flat and ball end mills, these reduce chipping and enhance tool longevity.

Size Factors

- Diameter: The diameter of an end mill affects cutting depth and speed. Smaller diameters are best for precision work, while larger ones handle bulk material removal effectively.

- Length: Longer end mills can access deeper features but may sacrifice rigidity.

Pros and Cons

- Benefits:

- High versatility in producing diverse shapes.

- Ability to manufacture high-precision components.

- Drawbacks:

- Significant tool wear, especially with harder materials.

- Requires careful alignment during setup to avoid inaccuracies.

End Milling Versus Other Milling Techniques

End milling distinguishes itself from face milling and slab milling. While face milling focuses on flat surfaces, end milling is tailored for intricate details. This unique capability underscores the significance of end milling in precision machining.

Conclusion

Understanding the intricacies of the end milling process—its techniques, types, and applications—is vital for anyone involved in CNC milling. By grasping these elements, manufacturers can enhance their machining processes and achieve outstanding results.