In the realm of industrial lighting, sealed LED lighting solutions for dusty industrial environments play a crucial role in ensuring safety and efficiency. These environments often present unique challenges, including the accumulation of dust and debris that can compromise traditional lighting fixtures. Understanding the key factors to consider when selecting these specialized lighting solutions is essential for maintaining optimal working conditions.

Understanding Sealed LED Lighting Solutions

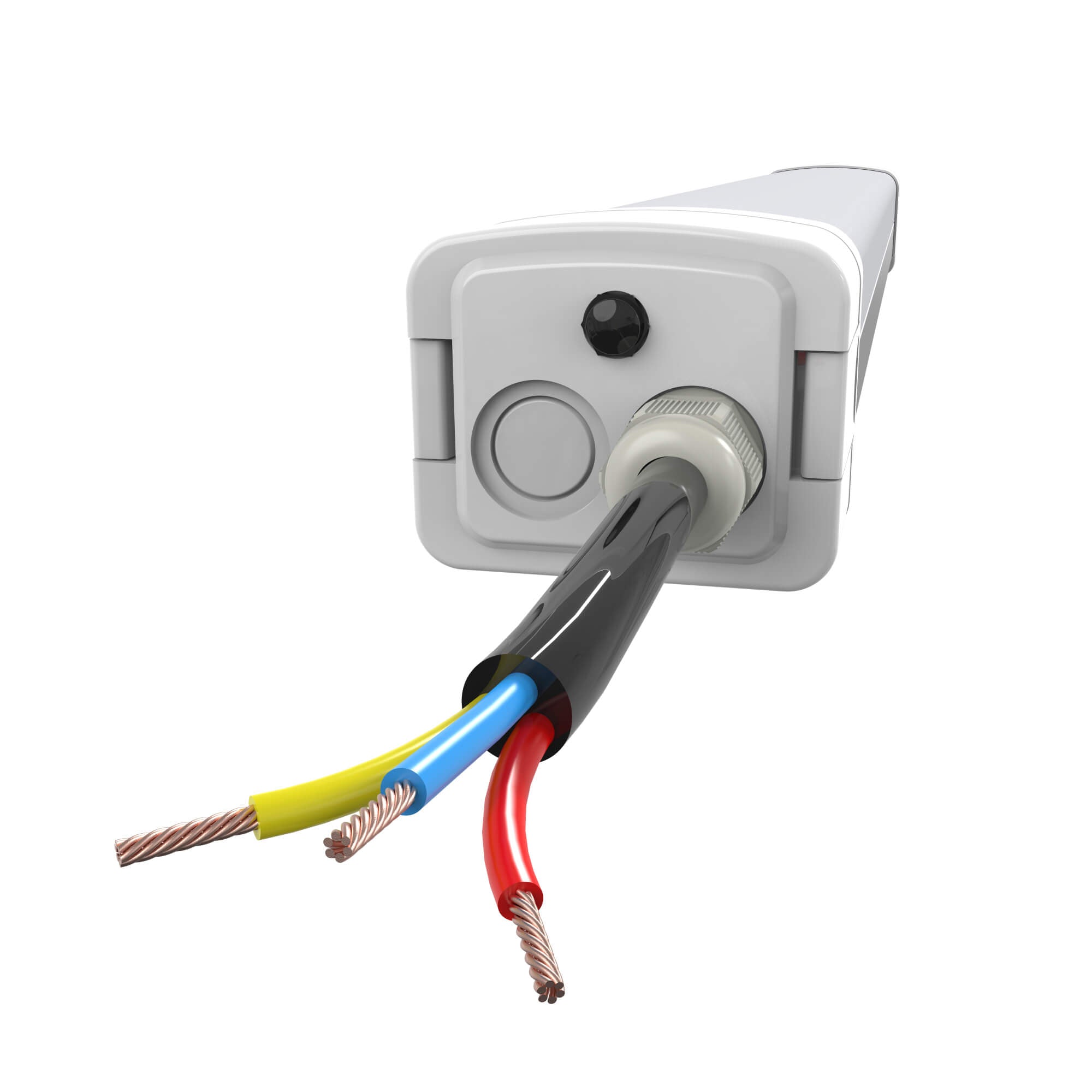

Sealed LED lighting solutions are designed to withstand harsh conditions, including dust, moisture, and extreme temperatures. These fixtures typically feature a robust construction that prevents contaminants from entering the housing, thus prolonging their lifespan and maintaining performance. But what specific attributes should you look for when choosing these lighting solutions?

Key Features to Look For

- Ingress Protection (IP) Rating: Ensure the lighting fixtures have a high IP rating, ideally IP65 or higher, which indicates resistance to dust and water.

- Durability: Look for materials such as polycarbonate or aluminum that can withstand impacts and harsh environments.

- Energy Efficiency: Opt for LED solutions that provide high lumen output while consuming less energy, contributing to lower operational costs.

- Color Temperature: Consider the color temperature that best suits your workspace, as it can affect visibility and worker comfort.

Benefits of Sealed LED Lighting Solutions for Dusty Environments

Implementing sealed LED lighting solutions for dusty industrial environments offers numerous advantages. These fixtures not only enhance visibility but also improve safety by reducing the risk of electrical failures caused by dust accumulation. Additionally, their energy efficiency can lead to significant cost savings over time. Wouldn't it be beneficial to invest in lighting that pays for itself through reduced energy bills?

Installation and Maintenance Considerations

When installing sealed LED lighting solutions, it is vital to consider the layout of your workspace. Proper placement can maximize light distribution and minimize shadows. Furthermore, maintenance is simplified due to the durability of these fixtures. Regular inspections are recommended to ensure they remain free of dust and debris, which can be easily wiped clean.

Where to Find Quality Sealed LED Lighting Solutions

For those seeking reliable options,  offers a range of high-quality sealed LED lighting solutions tailored for dusty industrial environments. Their products are designed with the latest technology to ensure longevity and performance.

offers a range of high-quality sealed LED lighting solutions tailored for dusty industrial environments. Their products are designed with the latest technology to ensure longevity and performance.

Conclusion

Choosing the right sealed LED lighting solutions for dusty industrial environments is essential for ensuring safety, efficiency, and cost-effectiveness. By focusing on key features such as IP ratings, durability, and energy efficiency, you can make informed decisions that enhance your workspace. Remember, investing in quality lighting is not just about illumination; it's about creating a safer and more productive environment for your workforce.