The Metraflow ultrasonic flowmeter offered by Titan Enterprises is an ideal choice for flow monitoring applications that call for a high degree of cleanliness, such as those found in the pharmaceutical, medical, semiconductor, and ultra-pure water markets. These industries all have a demand for extremely sterile environments. These are some of the markets that the ultrasonic flowmeters manufactured by Titan Enterprises serve.

In order to maintain conditions that are hygienic, sterile, and sanitary, the production processes that are typically utilized in these markets require flow measurement chemical resistant flow meter that are capable of coping with low flow rates and that are constructed from materials that are extremely pure.

The Metraflow ultrasonic flowmeter is an excellent choice for virtually any application in which it is essential to keep a clean environment. This is because it is constructed with a single clean bore measurement tube, making it a one-of-a-kind device. The Metraflow ultrasonic flowmeter is a high-performance device that is made out of a Perfluoroalkoxy Alkane (PFA) polymer. Its construction ensures that the device will last for many years. This polymer is resistant to a wide range of chemicals, and it also has the ability to accurately monitor process flow temperatures of up to 60 degrees Celsius (140 degrees Fahrenheit), as well as pressures of up to 28 bars (406 psi).

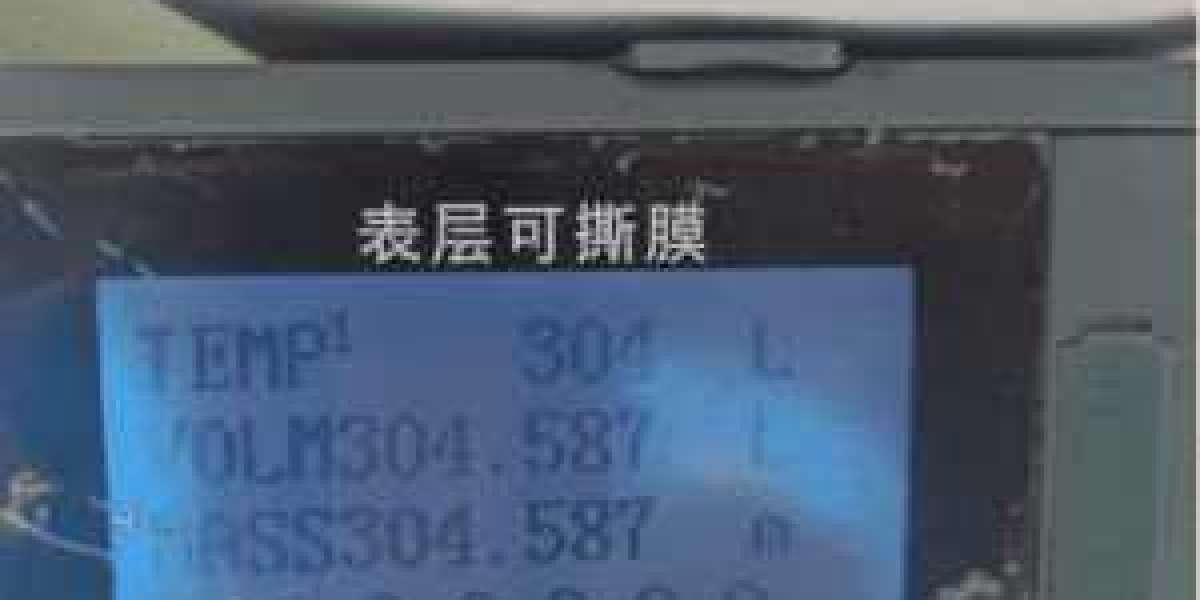

Measuring flow rates from 20 to 5000 ml/min, the Metraflow is a device that does not involve any invasive procedures. It utilizes ultrasonic technology that has been granted a patent and has a single measurement tube that has not been damaged in any way. Its accuracy is calibrated to within a reading of +/- 1.0% difference.

In order to make accurate measurements of liquid as it flows through a PFA flow tube, the Metraflow makes use of the patented transit time ultrasonic technology developed by Titan Enterprises. This technology was developed by Titan Enterprises. By utilizing a compact integrated electronic, display, and sensor package, it is possible to obtain superior performance from a single component. This will allow for greater efficiency. Because the connections to the computer and the operational components are kept separate, the Titan Interface Software can be used to configure and monitor the interface even while the system is operating normally. This is possible because the connections to the computer and the operational components are kept separate.

The analog and digital outputs, as well as the units and the time base, can all be configured by making use of the USB connector. Additionally, the time base can be adjusted. The user is provided with the ability to configure other parameters, such as flow alarms, cut off levels, and even data logging, according to their specific requirements by the highly flexible software system.

Titan Enterprises Ltd is a manufacturer of high-performance solutions, such as the Atrato ultrasonic flowmeter, Oval Gear flowmeters, low flow Turbine flow meters, and a flow instrument range. These products are all part of the company's flow instrument range. This company has been at the forefront of flowmeter innovation for over 40 years.

Titan's business philosophy of "pushing the envelope" by striving to do things a little differently and better has led to the sale of over 500,000 products in more than 50 countries around the world. Titan attributes these successes to the company's commitment to innovation. In addition to this, there is a repeat purchase percentage of 95% within the company. All of the flowmeters sold by Titan Enterprises are first designed to be compliant with the standards established by ISO9001, then manufactured in accordance with those standards, and finally calibrated to an uncertainty of 0.25%.